Engineers use electricity to peek inside bridge cables for corrosion

2013-12-06 17:55:25

作者:MARCENE ROBINSON来源:

Rust is a civil engineer's nightmare.

Across the United States, more than 200 million trips are taken daily across bridges rated structurally deficient or in need of significant maintenance and yearly inspection. One major culprit: corrosion of reinforcing steel.

Now, however, UB researchers believe they can detect corrosion before the damage becomes severe by sending a jolt of electricity between opposite ends of steel cables. An inconsistency in the charge would alert them that the cable is suffering from corrosion and the bridge is in danger of falling.

“We need to be as accurate as possible to save money, time and lives.”

Tresor Mavinga, civil engineering and mathematics major

“The No. 1 priority of all civil engineers is the safety of the public,” says Tresor Mavinga, a UB senior civil engineering and mathematics major involved in the research. “Corrosion can affect any structure, not just bridges, and we don’t want that to happen. We need to be as accurate as possible to save money, time and lives.”

Led by Salvatore Salamone, assistant professor of civil engineering, Mavinga and Alireza Farhidzadeh, a civil engineering graduate student, embedded piezoelectric transducers — devices that convert a signal from one form of energy to another — onto each end of a wire.

They then fired one volt of electricity through the metal using ultrasonic-guided waves, which can travel a long distance with little loss in energy, while monitoring the charge received at each end. The experiment was repeated with the same wire after it was rusted with a saltwater mixture. Because the cables are corroded, most of the energy from the electrical charge will be lost during the transfer between transducers.

Since the sensors and transducers are permanently attached to the cable, engineers can test the wires remotely off-site.

The new method of testing could do away with time-consuming and expensive visual tests, which often rely on drilling through concrete to inspect the cables or spotting cracks in the concrete caused by increased stress on the weakened wires.

According to the Federal Highway Administration, corrosion problems have increased significantly over the past three decades and are likely to continue. The increase is in part due to the rising use of road de-icing salts, which are extremely corrosive to the protective films on metals.

Led by Salvatore Salamone, assistant professor of civil engineering, Mavinga and Alireza Farhidzadeh, a civil engineering graduate student, embedded piezoelectric transducers — devices that convert a signal from one form of energy to another — onto each end of a wire.

They then fired one volt of electricity through the metal using ultrasonic-guided waves, which can travel a long distance with little loss in energy, while monitoring the charge received at each end. The experiment was repeated with the same wire after it was rusted with a saltwater mixture. Because the cables are corroded, most of the energy from the electrical charge will be lost during the transfer between transducers.

Since the sensors and transducers are permanently attached to the cable, engineers can test the wires remotely off-site.

The new method of testing could do away with time-consuming and expensive visual tests, which often rely on drilling through concrete to inspect the cables or spotting cracks in the concrete caused by increased stress on the weakened wires.

According to the Federal Highway Administration, corrosion problems have increased significantly over the past three decades and are likely to continue. The increase is in part due to the rising use of road de-icing salts, which are extremely corrosive to the protective films on metals.

The steel cable tendon, which is found in most bridges, is suspended above a saltwater mixture with ultrasonic sensors attached at both ends for corrosion monitoring.

Photo: Marcene Robinson

Improved testing is a needed step toward improvement of American infrastructure.

U.S. bridges were graded a C-plus by the American Society of Civil Engineers in its 2013 Report Card for America’s Infrastructure. And of the more than 17,000 bridges in New York, 12.5 percent are structurally deficient and 27 percent are considered functionally obsolete.

The report adds that one out of nine of the nation's bridges is structurally deficient and that more than 30 percent of bridges have exceeded their 50-year design life; the average age of the nation's bridges is currently 42 years.

The report adds that one out of nine of the nation's bridges is structurally deficient and that more than 30 percent of bridges have exceeded their 50-year design life; the average age of the nation's bridges is currently 42 years.

责任编辑/任盼盼

中国腐蚀与防护网官方QQ群:140808414

《中国腐蚀与防护网电子月刊》征订启事

投稿联系:郭静 电话:010-82387968-802

QQ: 815397784 邮箱:guojing733@163.com

《中国腐蚀与防护网电子月刊》征订启事

投稿联系:郭静 电话:010-82387968-802

QQ: 815397784 邮箱:guojing733@163.com

-

标签: corrosion, bridge cables , electricity

相关文章

官方微信

《中国腐蚀与防护网电子期刊》征订启事

- 投稿联系:编辑部

- 电话:010-62313558-806

- 邮箱:fsfhzy666@163.com

- 中国腐蚀与防护网官方QQ群:140808414

点击排行

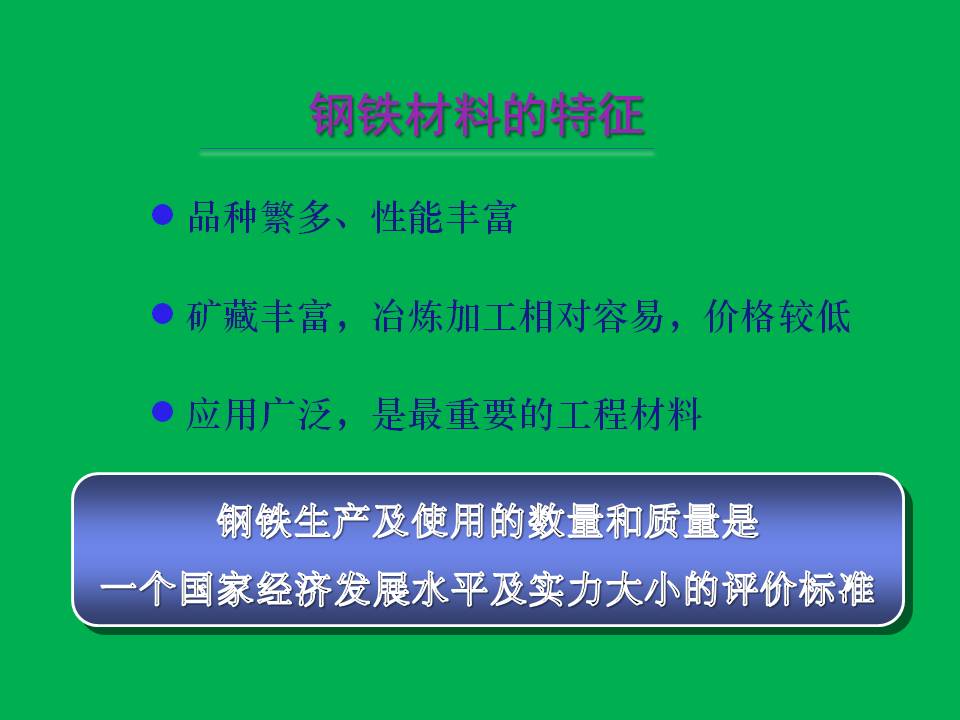

PPT新闻

铝合金LDH自修复自抗菌膜层构建

点击数:466

碳钢及合金钢应用与区别

点击数:393