冰虽然是自然环境中一种常见的现象,但却对生产生活造成很大影响,尤其是对船舶航运、电力传输、风力发电、航空运载以及道路交通等行业会产生严重破坏。近年来,随着极地航线的开辟以及极地丰富资源的开发利用,极地航行船舶和海工装备的船体、上层建筑及各类设备的覆冰问题逐渐成为研究关注的热点。以极地舰船运输为例,在极低温的气候影响下,船舶表面、上层建筑及各类设备会覆盖大量的冰雪,使船舶吃水深度及重心发生变化,从而降低船舶稳定性和上层建筑结构可靠性。此外,设备上积累的大量覆冰还会影响设备运行,带来严重安全风险。为保障极地船舶航行及各类装备的安全运行,不仅要考虑船舶总体防除冰设计,还需要考虑防除冰新型材料在船舶上的应用。

近年来,研究人员提出了大量新型的方法和技术,以期能够从根本上减缓和抑制结冰,达到防冰和除冰兼顾的效果。这其中在材料表面涂覆抗冰涂层是一种便捷实用、高效并极具前景的技术。该类抗冰涂层不仅可以降低冰的附着力,还可以延缓表面的水冻结,从而抑制涂层表面的覆冰积累[3]。目前超疏水涂层是抗冰涂层的研究热点。

受自然现象的启发,如荷叶表面自清洁和水黾的“防水”腿,超疏水涂层引起了广泛的关注。超疏水涂层在自清洁、减阻、油水分离、防腐蚀、防污和防冰等方面具有巨大的研究价值[4~9]。由于超疏水表面本身存在特殊的浸润特性,如接触角>150°,滚动角<10°,使得超疏水涂层能够在水滴结冰前,缩短水滴在表面的滞留时间,减少水滴结冰的概率[10]。在结冰过程中,超疏水涂层能够减缓水滴与基体材料表面间的热传递过程,延迟水滴结冰的时间;同样在水滴结冰后,可减小水滴与表面接触面积,降低冰与表面之间的附着力[11, 12]。大量研究表明这种超疏水特性可以起到很好的防冰除冰效果,如应用在风力发电叶片表面、输电导线表面、极地船舶上以及飞机部件上都可以抑制覆冰。其中将被动抗冰技术—超疏水涂层和传统的主动除冰方法—如电热、光热方法结合在一起可形成一种多功能抗冰策略,强化涂层技术和主动除冰方法的优势,得到一种全新的抗冰体系,这也是当前新型抗冰技术的研究热点。

本文首先简要介绍了固体表面浸润理论和结冰的热力学机理,然后详细分析了影响超疏水涂层抗冰性能的重要因素,具体综述了以超疏水性为基础的各类功能性涂层在抗冰中的应用。最后,总结了这类功能性涂层在抗冰领域的未来发展趋势和发展方向。

1 机理分析

1.1 超疏水表面的润湿性

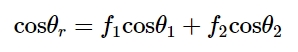

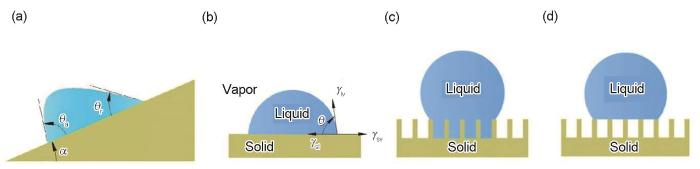

作为具有巨大应用价值的材料,超疏水材料表面特征需要从静态和动态进行描述。如图1所示,称静态的接触角θCA > 150°,动态的接触角滞后Δθ <10°的表面具有超疏水性[13]。将表面缓慢倾斜,附着于表面的水滴随着倾斜角度的增加会出现形态的变化。当倾斜角度达到一定程度时,液滴会发生滚动,记录液滴开始滚动的那一刻前后接触角,即对应的前三相接触点处的接触角为前进接触角(θa),对应的后三相接触点处的接触角为后退接触角(θr),从图1a可知前进接触角比后退接触角大,接触角滞后是指前进接触角和后退接触角之间的差值,即Δθ = θa -θr[15,16]。在实际的测量过程中,接触角滞后的数值并不好测量,与前进接触角和后退接触角相比,滑动角或滚动角能更直观便捷的表现接触角滞后的大小。

图1

图1 斜面上的接触角滞后和润湿理论模型

Fig.1 Contact angle hysteresis on an inclined plane (a) and wetting theory model: (b) Young model, (c) Wenzel model, (d) Cassie-Baster model

1.2 润湿理论模型

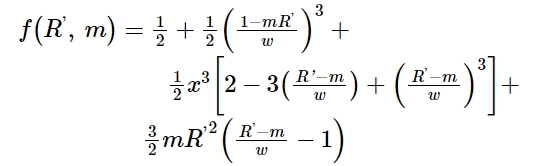

材料表面的润湿性与表面自由能及粗糙度有密切关系。表面自由能也称表面张力,用γ表示,指液体或固体内部分子之间相互作用而导致其表面的分子受力不均产生向内收缩的力,单位是J/m2或N/m2。影响润湿性的因素十分复杂,气液固三相不同化学性质、材料表面的微观形貌以及环境等因素都会影响润湿性。为便于分析研究不同材料的润湿性质,根据经典的润湿理论可归纳总结出3类润湿性模型[17]。

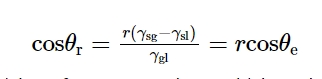

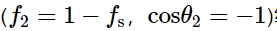

Young模型:Young提出化学性质稳定的液滴在光滑平整的理想刚性平面上稳定存在时,当达到平衡状态时,固-液-气三相接触线处所受合力为零,此时液滴的接触角由

这里

在该模型下,认为粗糙的固体表面其凹槽中存在空气,在与液体接触时,固体表面并没有被液滴完全浸润,见图1d,所以上述两种化学性质的固体表面可看做是固体和液体的组合,其复合界面由固-液

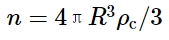

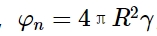

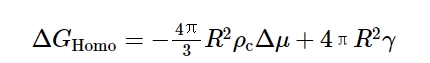

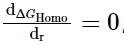

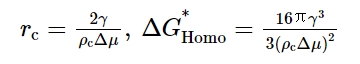

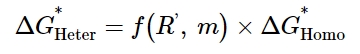

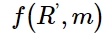

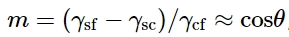

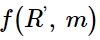

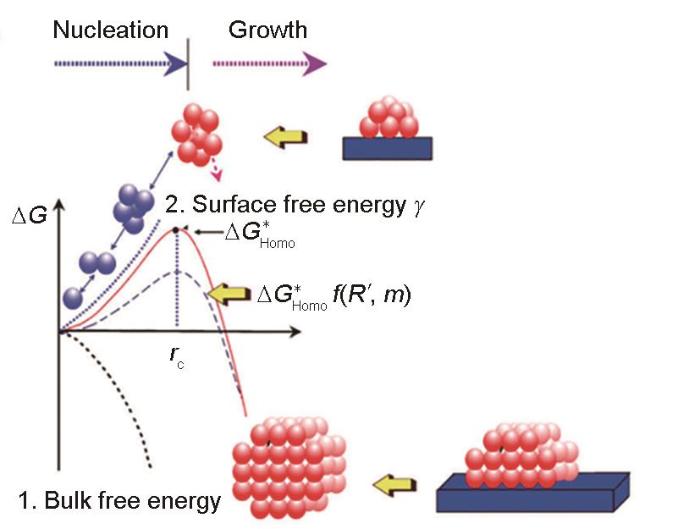

1.3 结冰理论

图2

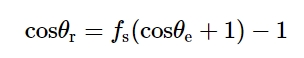

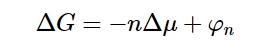

为常数时,曲率半径为

为常数时,曲率半径为

1.4 超疏水界面的抗冰特性

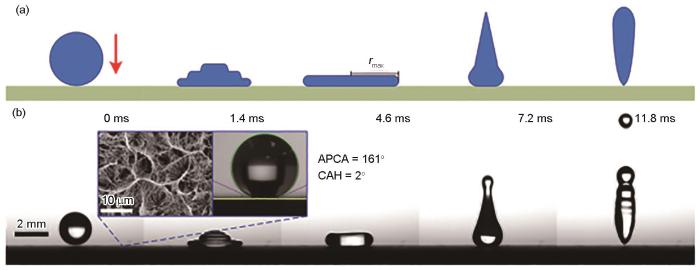

对于超疏水的抗冰特性可以从3个角度思考,即去除动态水滴、控制晶核形成和降低冰的附着力。通常水滴是以动态的方式滴落到固体表面,对于高静态接触角、低动态接触角滞后的超疏水表面(Cassie-Baster状态),水滴滴落至表面时会发生反弹或者滚落,极大的减少了接触时间,避免了低温下水滴与表面接触并产生结冰。因此,动态的抗冰特性可以通过液滴在样品表面的撞击接触时间和接触过程来评价。对于具有低接触角滞后的超疏水表面,在微纳米表面结构之间存在大量的气袋。空气可以有效地充当超疏水表面和水滴之间的热屏障,令水滴与表面之间的相互作用较弱,水滴仍然保持球形,从而使液滴与表面的接触面积最小。通过这种方式,水滴很容易被外力推离表面,从而防止它们被冻结[36~38]。对于亲水表面,液滴撞击到表面会出现润湿表面的情况;对于疏水表面,液滴撞击表面的过程见图3,撞击的过程可分为4个时间点:接触时刻、最大铺展时刻、最大延伸时刻(从冠状形成开始)和脱离表面时刻[39]。在这样一个极疏水的表面液滴的最小撞击时间可达到12 ms,接触时间取决于液体的性质、表面的润湿性和水滴的运动学参数。

图3

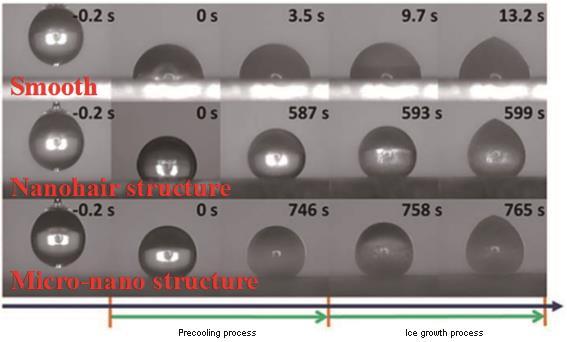

当液滴停留在固体表面,随着温度的降低,在0℃左右会很快发生结冰。如前所述,在日常环境中所见结冰现象基本是非均匀形核,在冰晶形核过程中,当突破自由能垒后晶核会稳定并很快成长成冰。超疏水材料具有抑制晶核形成的特性,主要体现为降低液滴结冰温度和延长液滴结冰时间[23]。Cassie-Baster润湿模型下的超疏水表面,其存在的微纳米分层的粗糙结构有利于捕获液滴下面的气袋。空气相比固体表面传热效率低很多,是一种很好的保温层,减缓了水滴和基体间的热交换,这种热屏障可以降低液滴的过冷程度,从而降低液滴的结冰温度。同时根据经典形核理论,接触角越大,冰核形成的自由能垒越大,较大的静态接触角也减少了液滴和表面的接触面积,减少了形核位置和概率,最终使得形核速率变慢,形核难度变大,从而延缓了液滴的结冰时间[40, 41]。Shen等[42]在金属衬底上制备了微尺度规则阵列和纳米毛层次结构,并用含氟硅烷进行修饰后获得超疏水表面,研究表明超疏水表面可以延迟结冰时间达到765 s,对晶核的形成有明显的抑制作用,见图4。微纳米结构的超疏水表面相比纳米结构的超疏水表面延迟结冰时间更长,可见微纳米结构在抗冰作用中是非常重要的。

图4

在低温下,对于长时间停留在表面的液滴总是会发生结冰,具有低的冰附着力的表面可以便于借助外力使冰从表面脱落,减少覆冰。冰在固体材料表面的强粘附性在很大程度上是由于极性冰分子和固体分子之间的强相互作用,这通常是由氢键、范德华力和直接静电相互作用引起的[43, 44]。研究表明[16],Cassie-Baster状态下的超疏水表面具有低的冰附着力。它会将空气储存在分层的微纳米结构中,在一定载荷下,空气提供足量的空隙,减少了冰与表面的接触面积和冰分子与固体分子之间的直接静电相互作用,达到降低粘附强度的效果。冰的粘附强度可以通过剪切或拉伸粘附试验来表征,但由于目前没有形成冰粘附试验的标准文件,研究人员均采用自行搭建的设备进行实验。

2 基于超疏水的功能性抗冰涂层的研究进展

自从发现超疏水材料具有抗冰作用后,研究人员开发了大量以超疏水为基础的抗冰涂层。然而,超疏水涂层的抗冰性能受到诸多内外因素的影响,探索解决现存问题的新方法尤为重要。近年来将不同技术、不同材料和超疏水结合在一起的新方向引起了广泛关注,如利用光热、电热等技术与超疏水结合在一起形成的多功能化抗冰涂层,这也是拓宽抗冰超疏水涂层的重要思路。基于此,本部分对这些技术和材料进行了归纳总结。

2.1 超疏水涂层

超疏水涂层具有优异的抗冰性能,正成为目前的研究热点。构成超疏水表面的条件是低表面能表面和微纳米粗糙结构,制备方法通常可分为两类:一类是典型的多步法,通常包括在低表面能表面构造微纳米粗糙度和先在表面构造粗糙结构再通过低表面能物质化学改性,具体技术有刻蚀法、沉积法、模板法、溶胶-凝胶法和层层自组装法等[17, 45~47];另一类是一步法,通过在低表面能物质成膜过程同时形成表面粗糙度,构造出微纳米结构的超疏水表面,具体技术有原位生成法、相分离法和一步喷涂法等[48~50]。如Lo等先通过化学刻蚀和水热法在Al表面制备出微纳米结构,然后将聚二甲基硅氧烷-三乙氧基硅烷(PDMS-TES)和全氟癸基三乙氧基硅烷(FD-TMS)以不同的比例混合修饰到微纳米结构表面上,PDMS-TES与铝表面为共价键结合可以提高涂层耐久性。对冰附着力和延迟结冰时间进行评估表明,即使在100次结冰/融化循环后,其对冰的粘附强度也能低至47 kPa[51]。

以各种超疏水抗冰涂层制备方法为基础,对所用材料、冰的附着力和延时结冰时间等进行总结和归纳,具体内容见表1。

表1 超疏水抗冰涂层的制备方法及各项性能表征总结

Table 1

| Preparation method | Materials / substrate used |

The adhesion of ice |

Delayed freezing time |

Other performance | Citation |

|---|---|---|---|---|---|

| Anodizing/spraying process |

F-SiO2, PDMS/ Aluminum plate |

26.3 kPa vs 821.9 kPa at -20oC |

276.2 s vs 4.8 s at -15oC |

30 icing / deicing cycles, 12.4 ms droplet dynamic bounce time |

|

| Laser etching /hydrothermal/chemical modification |

FAS-17 modifies the TiO2 / Ti6Al4V Titanium alloy plate |

70 kPa vs 700 kPa at -10oC |

765 s vs 13.2 s at -10oC |

17 ms droplet dynamic bounce time |

|

|

Template method

|

CF, PEEK, FAS-17/ Aluminum plate |

30.5 kPa vs 413 kPa at -20oC |

514 s vs 54 s at -20oC |

Simple preparation and high mechanical durability |

|

| Two-step spraying method |

PU, DE@HD-POS/ Aluminum plate |

50.8 kPa vs 819 kPa at -10oC |

315 s vs 52 s at -15oC |

13.25 ms droplet dynamic bounce time |

|

| Chemical etching / modification |

AgNO3, stearic acid/ Tinplate |

|

621s vs 295 s at -15oC |

10 icing / deicing cycles

|

|

|

One-step spraying method

|

F-SiO2, FSC/ Tinplate

|

27 kPa vs 1600 kPa at -20oC |

1765 s vs 170 s at -20oC |

20 icing / deicing cycles, high peeling resistance, wear resistance and durability |

|

|

Phase separation method |

SAN, SiO2/ ASA resin |

5040 s vs 540 s at -10oC |

Good self-cleaning performance |

||

| One step impregnation method |

PVDF, SiO2/ Aluminum plate |

Reduced 40% at -20oC |

273 s vs 65 s at -20oC |

18 icing / deicing cycles | |

| Layer upon layer self-assembly method |

TMES-SiO2/ Aerospace composite board |

53.6 kPa vs 335.3 kPa at -15oC |

195 s vs 77 s at -15oC |

High mechanical durability and wear resistance |

|

2.2 功能性光热/超疏水涂层

为扩展超疏水涂层的实际应用,近年来研究人员发展了一种新型的主动除冰和被动抗冰策略,在同时具有疏水性和光热功能的超疏水涂层方向进行了大量研究,最大限度的提高了抗冰效果。

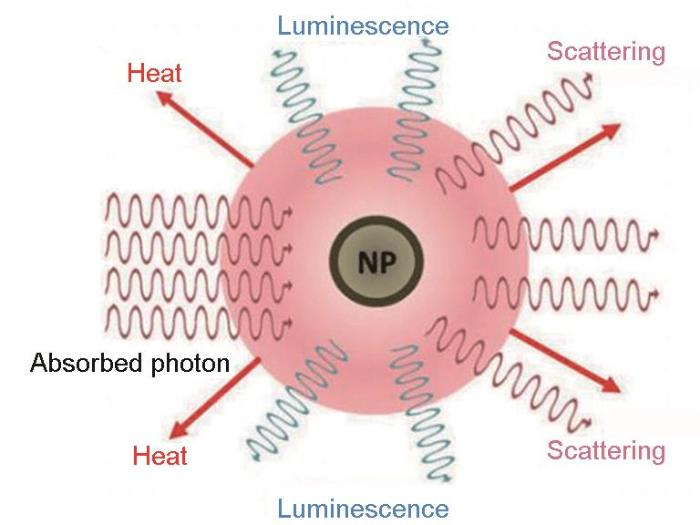

图5

图5 光热材料光照生热过程原理

Fig.5 Schematic diagram of the light-emitting thermogenic process of photothermal materials

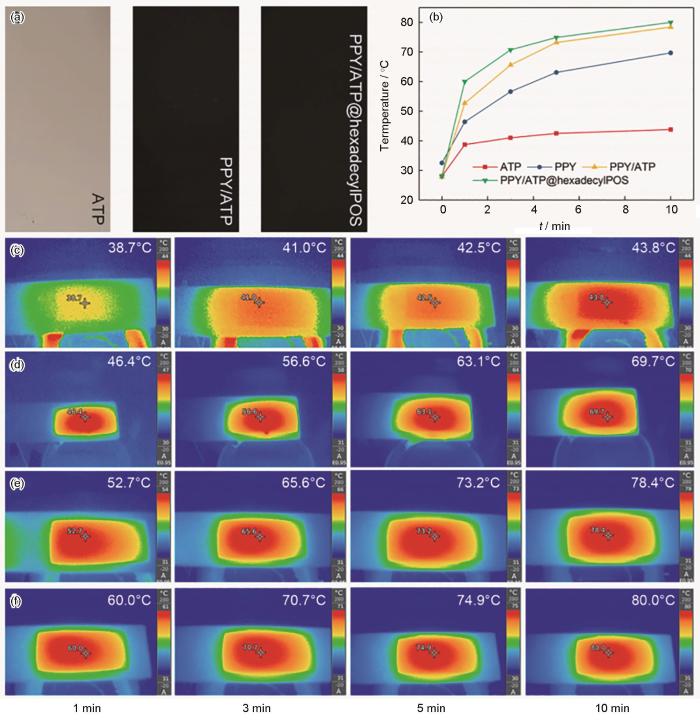

目前应用在光热涂层中的材料可分为金属纳米材料、碳结构材料和有机纳米材料(导电聚合物)等。不同材料由于其结构和性质不同,光热机制也是不一样的。金属纳米材料的光热机制与纳米颗粒和入射光发生表面等离子体共振作用有关,热量是由表面电流通过发热产生的弛豫产生的。碳结构材料的光热机制与π等离子共振有关(这种等离子体与碳原子之间的π键有关,属于光诱导的集体电荷运动)。导电聚合物的光热机制与光诱导载流子电流的弛豫有很大关系[62, 63]。Xie等[64]通过将PPY/ATP@hexadecylPOS悬浮液和有机硅树脂的混合物喷涂到Al板上制备出一种高效无氟、抗冰的光热超疏水涂层。研究表明,PPY/ATP@hexadecylPOS涂层在一个太阳光照下相比而言有最高的光热转换温度,10 min可升至最高温度80℃,见图6。而且在-10℃环境下对水滴延时结冰时间达330 s,在一个太阳下同样的环境延时结冰时间可达600 s,在-10℃冰的附着力只有51.6 kPa。文中的模拟室外环境研究表明该涂层有非常快的光热除冰和长效的抗冰性能[64]。

图6

图6 ATP、PPY/ATP和PPY/ATP@十六烷基POS涂层和其在1个太阳光照下的表面温度随照射时间的变化,以及相应的ATP、PPY、PPY/ATP和PPY/ATP@十六烷基POS涂层在一定时间间隔内的红外图像[64]

Fig.6 ATP, PPY/ATP and PPY/ATP@hexadecylPOS coatings (a), their surface temperature changes with irradiation time under 1 sun (b) and the corresponding infrared images of the ATP (c), PPY (d), PPY/ATP (e)and PPY/ATP@hexadecylPOS (f) coatings at certain time intervals[64]

基于此,对目前光热超疏水多功能涂层的制备方法、材料、冰的附着力和延时结冰时间等性能进行总结和归纳,具体内容如表2所示。

表2 光热超疏水抗冰涂层的各项性能表征总结

Table 2

| Preparation method |

Photothermal materials / substrate |

Delayed freezing time | Adhesion of ice | Photothermal performance |

Citation |

||

|---|---|---|---|---|---|---|---|

|

Heating temperature under light |

Ice melting time under light |

Other performance |

|||||

| Laser etching and PFTS modification | Moth eye structure/Aluminum plate |

1085 s vs 300 s at -15oC |

|

The temperature rises to 80oC in 300 s/ by 1 sun (0.1 W/cm2) |

Melt the 10 mm × 10 mm ice in 240 s /by one sun |

20 icing / deicing cycles, High durability and wear resistance |

|

| Electron beam vapor deposition |

TiN,PTFE/Q234

|

78 s vs 20 s at -10oC |

|

The temperature rises to 85oC in 600 s/ by NIR irradiation, 808 nm, 0.1 mW/cm2 |

Melt the 25 mm × 25 mm × 3 mm ice in 50 s/ by NIR irradiation, 0.1 W/cm2 |

High temperature thermal stability, excellent corrosion resistance |

|

|

Spraying method

|

SiC, SiO2/ copper mesh

|

82 s vs 43 s at -30oC |

1.66 kPa vs 5.87 kPa |

The temperature rises to 48.3oC in 60 s /by NIR irradiation, 808 nm, 2.5 W/cm2 |

Melt the ice in 300 s/by NIR irradiation (2.5 W/cm2) |

High heat conversion efficiency, high flexibility and wear resistance |

|

|

Spraying method

|

Melanin nanoparticles/glass |

144 s vs 63 s at -20oC |

25.65 kPa vs 104.13 kPa |

The temperature rises to 68.5oC in 600 s /by 1 sun (0.1 W/cm2) |

Melt the 3 mm thick ice in 600 s/by one sun (0.1 W/cm2) |

10 icing / deicing cycles

|

|

|

Spraying method

|

FMWCNTs/Aluminum plate |

364 s vs 23 s at -10oC |

|

The temperature rises to 55.7oC in 600 s /by 1 sun (0.1 W/cm2) |

Melt the 2 mm thick ice in 900 s/by one sun (0.1 W/cm2) | Photothermal self - healing performance, high heat conversion efficiency |

|

|

Spraying method

|

SiO2/SiC/ EVA Plate

|

152 s vs 29 s at -30oC |

4.42 kPa vs 52.17 kPa |

The temperature rises to 315oC in 10 s /by NIR (808 nm) |

Melt the 25 mm × 35 mm × 3 mm ice in 180 s /by NIR (808 nm) |

5 icing / deicing cycles

|

|

|

Spraying method

|

SiC/CNTs/ EVA Plate

|

66 s vs 15 s at -30oC |

2.65 kPa vs 25.65 kPa |

The temperature rises to 172.6oC in 60 s /by NIR (808 nm) |

Melt the 25 mm × 45 mm × 30 mm ice in 250 s/by NIR (808 nm) |

high heat conversion efficiency

|

|

|

Spraying method

|

Fe3O4 / glass

|

2878 s vs 50 s at -15oC |

213.7 kPa vs 399.9 kPa |

The temperature rises to 38oC in 300 s /by fluorescent lamp (75 W) |

Melt the ice in 232 s/by fluorescent lamp (75 W) |

10 icing / deicing cycles

|

|

2.3 功能性电热/超疏水涂层

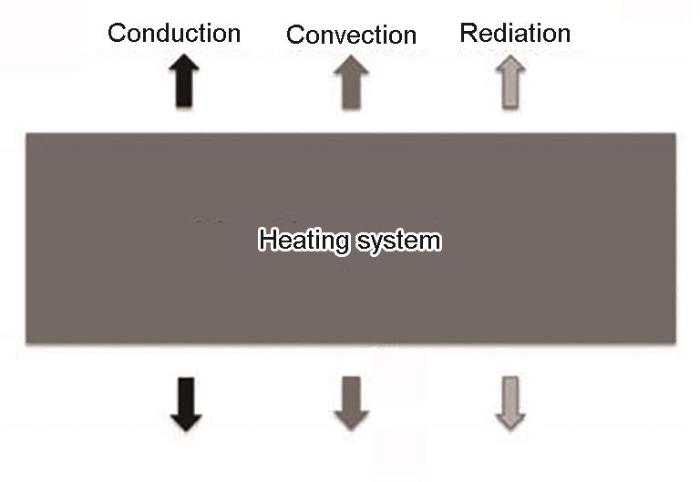

电热系统是一种广泛应用于飞机、电缆的主动防除冰策略,通过在表面制备嵌入式的电加热元件或者导电复合材料,接通电源后,会产生焦耳热量并以热传导、热对流和热辐射的方式传输热量,见图7,可达到防除冰的效果,其具有高效率、高可控性等特点,如波音和空客都应用这种技术来进行防除冰[73]。作为电热系统中的重要一环,导电复合材料得到了广泛的关注和大量的研究。近年来,具有优异电子流动性的碳材料及其衍生物成为导电复合材料的研究热点,如碳纳米管(CNTs)[74~76],高度排列的碳纳米网[77]、石墨烯[78]、石墨烯纳米带(GNP)[79]、石墨纳米片(GNR)[80]、碳纤维(CF)[81]等。如将电热复合材料和超疏水涂层结合在一起,利用超疏水涂层优异的防冰性能,辅以电热系统进行结冰后的除冰,既可以减少能量消耗,又提高了防除冰的效果。

图7

图7 焦耳热传递示意过程

Fig.7 Schematic diagram of Joule heat transfer

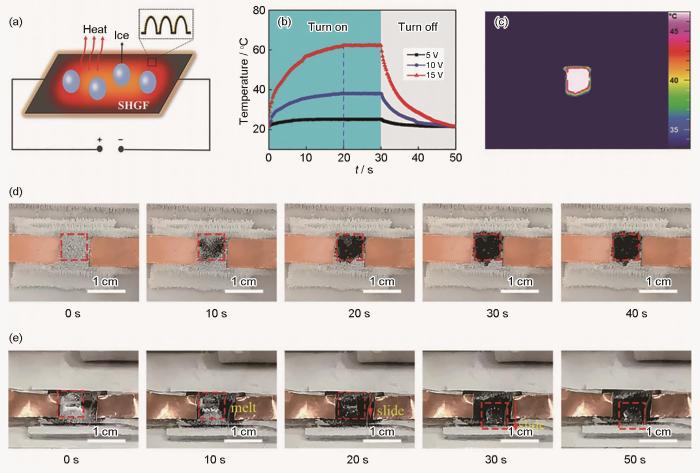

具有优异电学性能的CNTs是碳材料中应用最广泛的一种,将其与超疏水结构结合得到被动防冰和主动除冰的综合效果是研究人员的关注热点[82~85]。Chu等提出了一种重量轻、超疏水性、耐久性强、具有电热除冰性能的石墨烯基(FSGF-T200)薄膜,研究表明,FSGF-T200薄膜不但对水滴延时结冰可以延长至8倍左右,而且对冰的附着力可以降低至原先的0.2倍。此外,FSGF-T200薄膜也具有较好的电热性能,在15 V电压下可以在20 s内迅速升温到62.2℃,而且温度分布是均匀的。除霜和除冰实验发现,在15 V电压下FSGF-T200薄膜30 s内可以完全除霜,20 s内可以让冰层融化滑动,见图8[86]。

图8

图8 FSGF-T200薄膜的电热除冰原理,在不同施加电压下的焦耳加热曲线和施加15 V直流电压后FSGF-T200的红外图像,除霜与除冰过程[86]

Fig.8 Schematic diagram of electrothermal deicing for FSGF-T200 film (a), Joule heating profile of the FSGF-T200 under different applied voltages (b), infrared images (c), defrosting (d) and deicing (e) process of the FSGF-T200 after applying a DC voltage of 15 V[86]

电热材料具有高效的除冰、解冻效率,但是往往会存在功耗大的问题,将其与超疏水技术结合在一起,可以达到一体化防冰和除冰的效果,发展高灵活度、高耐久性和低功耗的电热超疏水材料和技术也是未来抗冰涂层的一个重要研究方向。

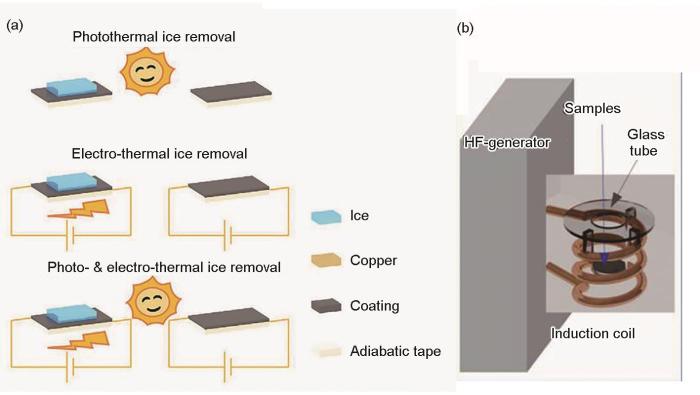

2.4 其他复合功能性超疏水涂层

目前有较深入研究的功能性材料包括对有磁性的材料添加磁场诱导其生热,通过阳光和电压对同时具备电热光热的材料诱导其生热,作用过程见图9。在研究超疏水抗冰涂层材料的过程中,科研人员也发现将这些具有磁性的材料和同时具有光热、电热的材料等与超疏水结构结合在一起会有更好的抗冰效果,对开拓超疏水涂层的应用具有更重要的意义,也将成为未来的研究热点。

图9

图9 涂层光生热、电生热、光电生热和磁生热作用过程

Fig.9 Photothermal, electro-thermogenic, photo- & electro-thermal process (a) and magnetothermal process (b) of coatings

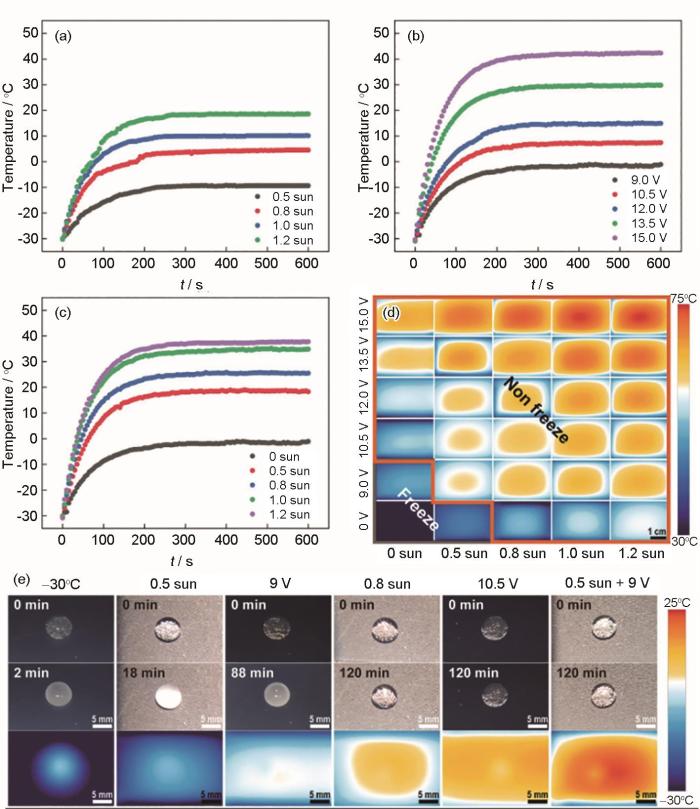

图10

图10 PESC涂层在施加不同光强下的光照生热曲线,在施加不同电压下的焦耳生热曲线,在9.0 V电压下施加不同光强下的生热曲线,在同时施加不同电压和光强下的红外图像,在施加不同电压和光强下的水滴结冰过程和红外图[88]

Fig.10 Light heating curves of the PESC coating at different applied light intensities (a), Joule heating profile at different applied voltages (b), heat generation curve under different light intensity applied at 9.0 V voltage (c), infrared images at different voltages and light intensities (d), water droplet icing process and infrared diagram at different applied voltages and light intensity[88]

3 总结与展望

自然界中常见的结冰现象,对人们的生活会产生很大影响,更重要的是对船舶、航空、电力等行业会造成严重的危害和损失。究其原理,结冰过程是在驱动力的作用下,随机自发形成不稳定的晶核,当晶核达到一个临界尺寸(超过了活化势能)就能够稳定存在并不断膨胀,最终导致整个体系的结晶。

超疏水涂层可以延缓这样的结冰过程,从而使得其在抗冰领域得到了广泛的应用。这与超疏水本身的低表面能物质和微纳米粗糙度结构有密切关系,事实上对于超疏水结构,也有Young、Wenzel和Cassie-Baster等几种不同的润湿状态,这对其性能会产生很大影响。对于超疏水的抗冰特性可以分为三个角度,即动态水滴的去除、晶核形成的控制和冰附着力的降低。然而超疏水涂层表面存在微纳米粗糙度结构容易被破坏,低表面能物质与基质的粘附力不强的缺陷,这使得其应用受到了一定程度的限制。结合已经成熟应用的电热、光热除冰技术,将此类主动除冰技术与被动抗冰的超疏水材料结合在一起,是一种非常有潜力有应用价值的抗冰策略。目前该方向研究的主要有电热超疏水涂层、光热超疏水涂层、电热+光热+超疏水涂层以及其他一些功能化的超疏水涂层。

总的来说,超疏水涂层在抗冰领域具有很大的应用价值,特别是功能化的超疏水涂层可以达到防冰和除冰的协同效果,可为极地船舶运输和科研考察等提供高效的抗冰解决方案。与此同时,制备方便、快速、低成本、对人体无毒和环境友好的超疏水抗冰涂层也是目前迫切需要解决的问题。尽管超疏水涂层将花费很长时间来实现其在工业领域的广泛应用,但这是值得我们研究和探索的。

参考文献

Dynamics of ice nucleation on water repellent surfaces

[J].The impact of road de-icing salts (NaCl) on colloid dispersion and base cation pools in roadside soils

[J].Bio-inspired strategies for anti-icing

[J].Copper-based superhydrophobic materials with long-term durability, stability, regenerability, and self-cleaning property

[J].Spray-coated superhydrophobic surfaces with wear-resistance, drag-reduction and anti-corrosion properties

[J].

Dynamic study of liquid drop impact on supercooled cerium dioxide: anti-icing behavior

[J].Superhydrophobic Cu2S@Cu2O film on copper surface fabricated by a facile chemical bath deposition method and its application in oil-water separation

[J].Wettability and drag reduction of a superhydrophobic aluminum surface

[J].Antibacterial properties and chemical stability of superhydrophobic silver-containing surface produced by sol-gel route

[J].Mechanism of supercooled droplet freezing on surfaces

[J].Reducing ice adhesion on nonsmooth metallic surfaces: wettability and topography effects

[J].Ice-phobic gummed tape with nano-cones on microspheres

[J].Superhydrophobic surfaces: from structural control to functional application

[J].Durable superhydrophobic and superamphiphobic polymeric surfaces and their applications: a review

[J].A review on special wettability textiles: theoretical models, fabrication technologies and multifunctional applications

[J].Bioinspired surfaces with superwettability for anti-icing and ice-phobic application: concept, mechanism, and design

[J].Recent progress in the preparation, properties and applications of superhydrophobic nano-based coatings and surfaces: a review

[J].Review on the recent development of durable superhydrophobic materials for practical applications

[J].Recent progress in the fabrication and characteristics of self-repairing superhydrophobic surfaces

[J].Nature inspired structured surfaces for biomedical applications

[J].Bioinspired surfaces with superwettability: new insight on theory, design, and applications

[J].Superhydrophobic coatings on cellulose-based materials: fabrication, properties, and applications

[J].Superhydrophobic materials used for anti-icing Theory, application, and development

[J].Applications of superhydrophobic coatings in anti-icing: Theory, mechanisms, impact factors, challenges and perspectives

[J].A mini-review on recent developments in anti-icing methods

[J].Role of water solidification concepts in designing nano-textured anti-icing surfaces

[J].Control of ice nucleation: freezing and antifreeze strategies

[J].Structural transformation in supercooled water controls the crystallization rate of ice

[J].Fundamentals of icing and common strategies for designing biomimetic anti-icing surfaces

[J].Correlation between hierarchical structure of crystal networks and macroscopic performance of mesoscopic soft materials and engineering principles

[J].Interfacial effect of molecules on nucleation kinetics

[J].Heterogeneous two-dimensional nucleation and growth kinetics

[J].Size effect in heterogeneous nucleation

[J].A new kinetic model for three-dimensional heterogeneous nucleation

[J].Physics of icing and rational design of surfaces with extraordinary icephobicity

[J].Resistant energy analysis of self-pulling process during dropwise condensation on superhydrophobic surfaces

[J].Strategies for anti-icing: low surface energy or liquid-infused?

[J].Rapid fabrication of a dual-scale micro-nanostructured superhydrophobic aluminum surface with delayed condensation and ice formation properties

[J].Approaching the theoretical contact time of a bouncing droplet on the rational macrostructured superhydrophobic surfaces

[J].Exfoliation of amorphous phthalocyanine conjugated polymers into ultrathin nanosheets for highly efficient oxygen reduction

[J].Excellent static and dynamic anti-icing properties of hierarchical structured ZnO superhydrophobic surface on Cu substrates

[J].Superhydrophobic Ti6Al4V surfaces with regular array patterns for anti-icing applications

[J].Understanding the solid-ice interface mechanism on the hydrophobic nano-pillar structure epoxy surface for reducing ice adhesion

[J].Fabrication of robust and repairable superhydrophobic coatings by an immersion method

[J].Petal shaped nanostructures planted on array micro-patterns for superhydrophobicity and anti-icing applications

[J].Investigation of the static icing property for super-hydrophobic coatings on aluminium

[J].Droplet impact on the cold elastic superhydrophobic membrane with low ice adhesion

[J].Various curing conditions for controlling PTFE micro/nano-fiber texture of a bionic superhydrophobic coating surface

[J].Stable bionic superhydrophobic coating surface fabricated by a conventional curing process

[J].Recent progress in preparation and anti-icing applications of superhydrophobic coatings

[J].Nanoscale coatings derived from fluoroalkyl and PDMS alkoxysilanes on rough aluminum surfaces for improved durability and anti-icing properties

[J].Spraying fabrication of durable and transparent coatings for anti-icing application: dynamic water repellency, icing delay, and ice adhesion

[J].Superhydrophobicity and anti-icing of CF/PEEK composite surface with hierarchy structure

[J].Waterborne, non-fluorinated and durable anti-icing superhydrophobic coatings based on diatomaceous earth

[J].A study on the fabrication of superhydrophobic iron surfaces by chemical etching and galvanic replacement methods and their anti-icing properties

[J].An extremely chemical and mechanically durable siloxane bearing copolymer coating with self-crosslinkable and anti-icing properties

[J].Fabrication of superhydrophobic surface with desirable anti-icing performance based on micro/nano-structures and organosilane groups

[J].A simple fabrication of superhydrophobic PVDF/SiO2 coatings and their anti-icing properties

[J].Mechanically robust superhydrophobic coating for aeronautical composite against ice accretion and ice adhesion

[J].Spectrally selective absorption coatings and their applications: A review

[J].A review of high-temperature selective absorbing coatings for solar thermal applications

[J].Nanoparticles for photothermal therapies

[J].Material strategies for ice accretion prevention and easy removal

[J].Non-fluorinated and durable photothermal superhydrophobic coatings based on attapulgite nanorods for efficient anti-icing and deicing

[J].Moth-eye-inspired texturing surfaces enabled self-cleaning aluminum to achieve photothermal anti-icing

[J].Plasmon-mediated photothermal and superhydrophobic TiN-PTFE film for anti-icing/deicing applications

[J].Efficient and economical approach for flexible photothermal icephobic copper mesh with robust superhydrophobicity and active deicing property

[J].Superhydrophobic anti-icing coatings with self-deicing property using melanin nanoparticles from cuttlefish juice

[J].Robust photothermal coating strategy for efficient ice removal

[J].Superhydrophobic coatings on iodine doped substrate with photothermal deicing and passive anti-icing properties

[J].Superhydrophobic SiC/CNTs coatings with photothermal deicing and passive anti-icing properties

[J].Magnetic particle-based super-hydrophobic coatings with excellent anti-icing and thermoresponsive deicing performance

[J].Anti-icing and de-icing techniques for wind turbines: Critical review

[J].Transparent film heaters using multi-walled carbon nanotube sheets

[J].Enhancement of heating performance of carbon nanotube sheet with granular metal

[J].Self-heating fiber reinforced polymer composite using meso/macropore carbon nanotube paper and its application in deicing

[J].An advanced anti-icing/de-icing system utilizing highly aligned carbon nanotube webs

[J].Effective de-icing skin using graphene-based flexible heater

[J].Anti-icing and de-icing coatings based Joule's heating of graphene nanoplatelets

[J].Composites of graphene nanoribbon stacks and epoxy for joule heating and deicing of surfaces

[J].Carbon fiber mats as resistive heating elements

[J].Novel sandwich structural electric heating coating for anti-icing/de-icing on complex surfaces

[J].Development of high-efficient synthetic electric heating coating for anti-icing/de-icing

[J].

Nonaligned carbon nanotubes partially embedded in polymer matrixes: a novel route to superhydrophobic conductive surfaces

[J].Low-voltage and -surface energy SWCNT/poly(dimethylsiloxane) (PDMS) nanocomposite film: Surface wettability for passive anti-icing and surface-skin heating for active deicing

[J].FDTS-modified SiO2/rGO wrinkled films with a micro-nanoscale hierarchical structure and anti-icing/deicing properties under condensation condition

[J].One-pot preparation of fluorine-free magnetic superhydrophobic particles for controllable liquid marbles and robust multifunctional coatings

[J].