DP600双相钢在两种盐雾实验条件下的腐蚀行为对比研究

吕良兴, 周和荣, 肖葵, 但佳永, 姚望, 吴磊, 段凯欣

1. 武汉科技大学材料与冶金学院 武汉 430081

2. 北京科技大学 腐蚀与防护教育部重点实验室 北京 100083

3. 北京福田戴姆勒汽车有限公司 北京 101400

Corrosion Behavior of DP600 Dual Phase Steel in Two Accelerated Test Environments

LV Liangxing, ZHOU Herong, XIAO Kui, DAN Jiayong, YAO Wang, WU Lei, DUAN Kaixin

1. School of Materials and Metallurgy, Wuhan University of Science and Technology, Wuhan 430081, China

2. Key Laboratory of Corrosion and Protection,University of Science and Technology Beijing, Beijing 100083, China

3. Beijing Foton Daimler Automobile Company,Beijing 101400, China

摘要

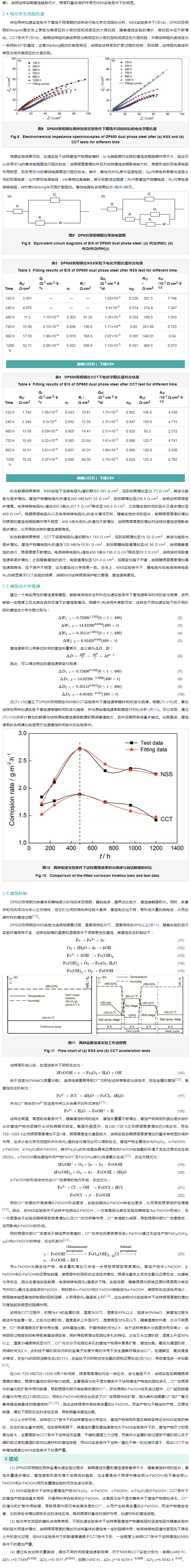

采用SEM、EDS、XRD以及EIS等技术,对比研究了DP600双相钢在中性盐雾(NSS)实验和循环盐雾腐蚀实验(CCT)两种不同加速实验条件下的腐蚀行为,并获得了腐蚀动力学规律。结果表明:在两种加速实验条件下,试样腐蚀失重均逐步增加,且CCT中的大于NSS中的;同时,初期腐蚀速率相差不大,在480 h时腐蚀速率均达到最大值,分别为1.89 g·m-2·h-1(NSS)和2.72 g·m-2·h-1(CCT)。两种实验条件下腐蚀产物主要是Fe3O4、α-FeOOH、γ-FeOOH、δ-FeOOH和α-Fe2O3,而CCT条件下同时也形成了较多的β-FeOOH。CCT条件下的锈层厚度大于NSS条件下的,且厚度增加趋势也更快。EIS结果表明:两种加速实验条件下试样溶液电阻和腐蚀产物膜电阻均逐步增大,电荷转移电阻均为先减小后增加。实验前期(≤480 h),NSS和CCT条件下的腐蚀速率可分别表达为:ΔD1-1=0.7349,ΔD2-1=0.3511;而在实验后期(>480 h),则分别为:ΔD1-2=14.6239,ΔD2-2=6.8542。

关键词: 金属材料 ; 双相钢 ; 中性盐雾实验 ; 循环腐蚀实验 ; 腐蚀速率模型

Abstract

Corrosion behavior of DP600 dual phase steel in two different accelerated test environments, namely neutral salt spray (NSS) test and cyclic salt spray corrosion test (CCT) was comparatively assessed by means of SEM, EDS, XRD and EIS. Results show that the corrosion mass loss of the steel in the two environments was gradually increased, and the amount of mass loss in CCT was higher than in NSS test. At the same time, there was no significant difference in the initial corrosion rate, however the maximum corrosion rate reached 1.89 g·m-2·h-1 (NSS) and 2.72 g·m-2·h-1(CCT) at 480 h respectively. The rust layer of the steel after the NSS test composed of Fe3O4, α-FeOOH, γ-FeOOH, δ-FeOOH and α-Fe2O3, besides, there existed significant amount of β-FeOOH for the rust layer of the steel after CCT test. The rust layer of the steel after CCT test is thicker than that after NSS test, whilst the thickness increases faster for the former rust layer. The EIS results show that the resistance of sample solution and corrosion product film are gradually increased in both accelerated tests, furthermore the charge transfer resistance decreased first and then increased. The corrosion rate of the steel during NSS test and CCT test can be described as: ΔD1-1=0.7349 and ΔD2-1=0.3511 for the early stage (t≤480 h), while ΔD1-2=14.6239 and ΔD2-2=6.8542 for the later stage (t>480 h) respectively.

Keywords: metallic materials ; dual phase steel ; neutral salt spray test ; cyclic salt spray corrosion test ; corrosion rate model

免责声明:本网站所转载的文字、图片与视频资料版权归原创作者所有,如果涉及侵权,请第一时间联系本网删除。

相关文章

官方微信

《中国腐蚀与防护网电子期刊》征订启事

- 投稿联系:编辑部

- 电话:010-62316606-806

- 邮箱:fsfhzy666@163.com

- 中国腐蚀与防护网官方QQ群:140808414

点击排行

PPT新闻

“海洋金属”——钛合金在舰船的

点击数:7130

腐蚀与“海上丝绸之路”

点击数:5741